OEM/ODM is always welcome! We have more than 10 years OEM/ODM experience. There are 2500 workers in our factory. There are 50 experienced engineers in our Research and Development department.

We have established strategic OEM (Original Equipment Manufacturer) partnerships with a lot of European and American companies.

OEM / ODM SERVICE

- We are looking forward to being your OEM/ODM strategic partner in China!

- We have more than 10 years of OEM/ODM experience.

- We have established strategic OEM (Original Equipment Manufacturer) partnerships with a lot of European and American companies.

Why Us?

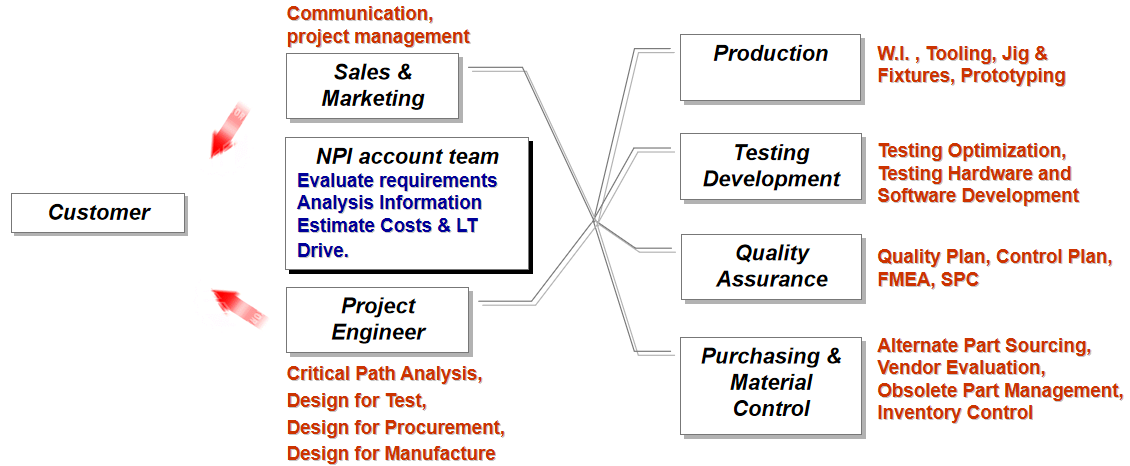

Customer Focus:

To understand customer needs requirements & preferences, we strive for extraordinary performance in every area to meet or exceed the customer’s expectations.

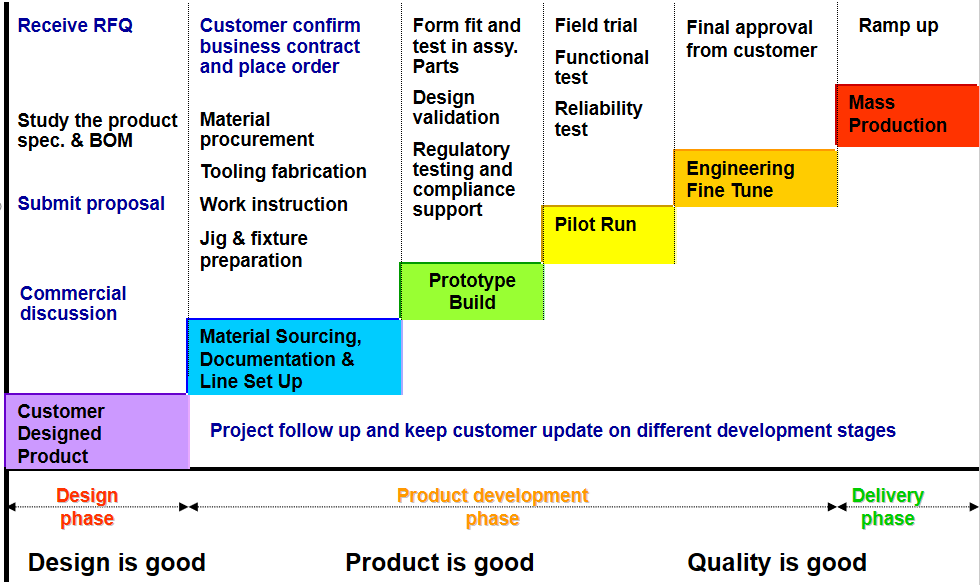

Excellence in Quality:

Our goal is to reduce variability and achieve zero defects for our production. A common set of metrics is used to measure, report, and drive improvement.

Continuous Improvement:

Constantly implement innovative technology throughout our manufacturing equipment & process, while parallel with the motivation, education, and development of all employees of Pearl Group. This is a joint responsibility shared between employees and management.